Post by suzsmokeyallan on Feb 12, 2011 10:29:57 GMT -5

Here are a few things to consider when setting about doing this conversion.

One: Most sets are supplied by either All Balls or Pyramid but there are others on the market. However this thread deals with these two brands which are most commonly used.

The Pyramid brand kit uses smaller diameter rollers and therefore has more of them than the All Balls kits bearings.

This makes the Pyramid bearing a better choice over the All Balls type since it spreads the load over a larger contact area of the races.

Two: Both bearing kits being mentioned above offer a lower bearing that has a race which is slightly too tall in its stack height.

You can see this issue when you place the lower outer race into the frame and offer the inner race up to it with the seal under it as a trial fit.

As it stands stock, the seal is almost outside the frames lower cups edge giving you basically no sealing there, so water easily enters the area and will quickly ruin the bearing.

Three: The additional material on the lower bearings inner race pushes the lower tree down further making the fork ears fit slack in the rubbers.

It also places the limit stop ear welded onto the frame very close to the top of those casted stops onto the lower tree.

To solve these three issues the inner races lower facing side that rests on the lower tree needs to be ground down approximately 2 to 2.5 mm.

As all bearings are hardened steel it needs to be ground precisely so the lower face remains perpendicular to the shaft hole. If you cant do this kind of work in you home shop then you will have to take it to a machine shop for alteration.

Removing this amount of material from the bearings larger end is not an issue since the section you are taking it from on the bearing is thick enough and has a shoulder thats strong enough for it.

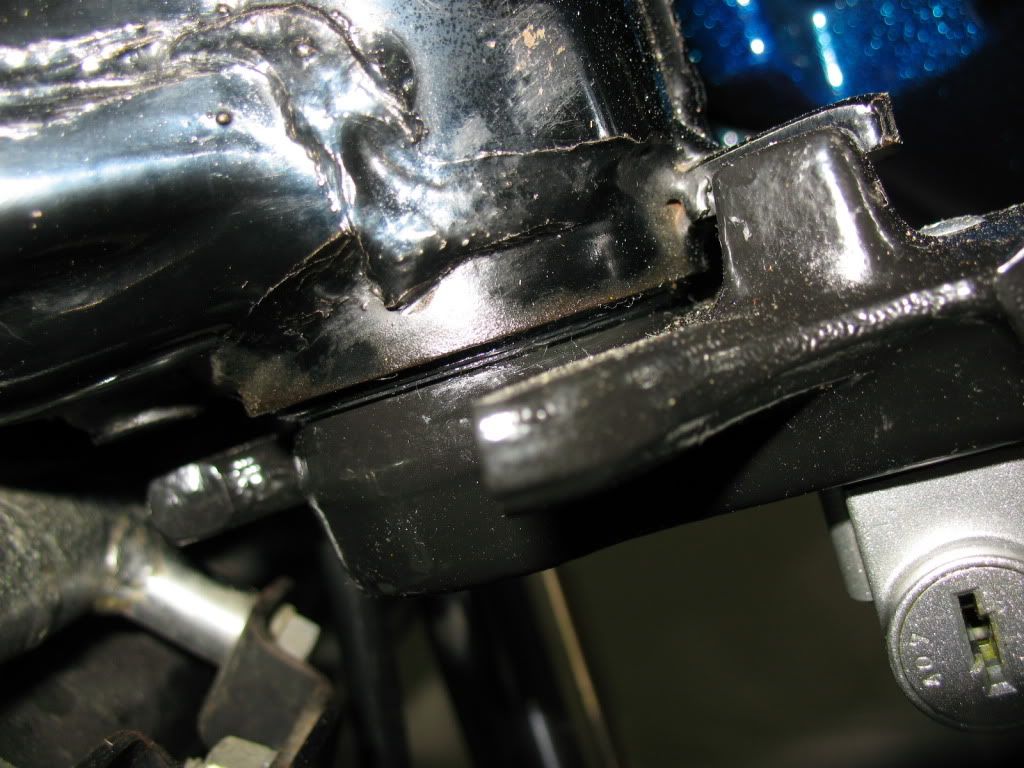

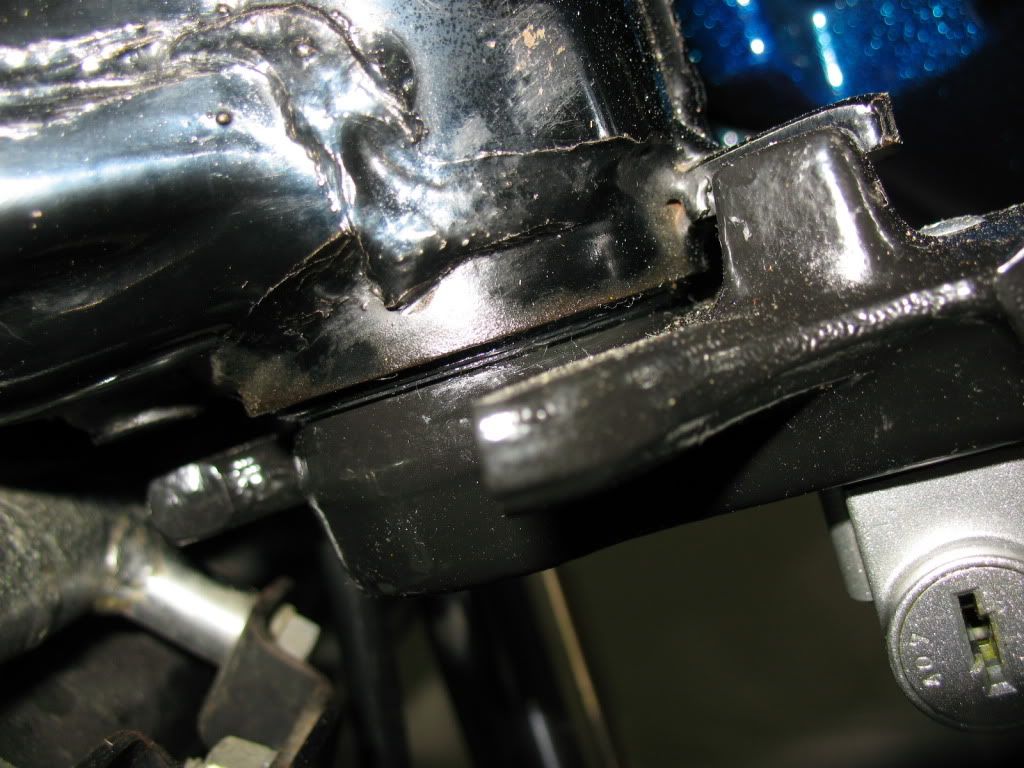

This is how it looks from the side view at the lower tree with the alteration. Now the seal is doing its designated job and the Head light ears also fit as they should with the correct amount of compression on the rubbers.

Even with this modification you can see the trees limit stops are still riding a bit high on the frame stop ear. More so at the front where its easy to see the original welding has pulled the stop upwards slightly.

I've since tapped it down with a block of wood just enough so its upper surface is closer to being flush with the ones on the lower tree.

One: Most sets are supplied by either All Balls or Pyramid but there are others on the market. However this thread deals with these two brands which are most commonly used.

The Pyramid brand kit uses smaller diameter rollers and therefore has more of them than the All Balls kits bearings.

This makes the Pyramid bearing a better choice over the All Balls type since it spreads the load over a larger contact area of the races.

Two: Both bearing kits being mentioned above offer a lower bearing that has a race which is slightly too tall in its stack height.

You can see this issue when you place the lower outer race into the frame and offer the inner race up to it with the seal under it as a trial fit.

As it stands stock, the seal is almost outside the frames lower cups edge giving you basically no sealing there, so water easily enters the area and will quickly ruin the bearing.

Three: The additional material on the lower bearings inner race pushes the lower tree down further making the fork ears fit slack in the rubbers.

It also places the limit stop ear welded onto the frame very close to the top of those casted stops onto the lower tree.

To solve these three issues the inner races lower facing side that rests on the lower tree needs to be ground down approximately 2 to 2.5 mm.

As all bearings are hardened steel it needs to be ground precisely so the lower face remains perpendicular to the shaft hole. If you cant do this kind of work in you home shop then you will have to take it to a machine shop for alteration.

Removing this amount of material from the bearings larger end is not an issue since the section you are taking it from on the bearing is thick enough and has a shoulder thats strong enough for it.

This is how it looks from the side view at the lower tree with the alteration. Now the seal is doing its designated job and the Head light ears also fit as they should with the correct amount of compression on the rubbers.

Even with this modification you can see the trees limit stops are still riding a bit high on the frame stop ear. More so at the front where its easy to see the original welding has pulled the stop upwards slightly.

I've since tapped it down with a block of wood just enough so its upper surface is closer to being flush with the ones on the lower tree.