Post by wayne on Apr 21, 2019 12:29:16 GMT -5

The following is an essay by Sam Costanzo to the Rotary Community. I have not modified it in any way. It has appeared in the past but I don't believe on this board.

As the years roll on since Sam's passing, I feel I need to give a background as we have so many new members and many new to the RE5 itself.

If you are unfamiliar with the name Sam Costanzo, let me tell you that it was synonymous with "Suzuki RE5" in the US. Sam was directly involved with the Suzuki RE5 project by invitation from Suzuki. He cut his rotary motorcycle teeth with his involvement with the Hercules W2000 and went on to become the leading expert on the Suzuki RE5 outside of the factory itself (he actually lectured on the RE5 at the Japanese factory). In Sam's museum you could take a tour through all sorts of RE5 versions and feast your eyes on literally hundreds of RE5's and W2000's (Sam even had Van Veens- yes, that's plural). No rotary motorcycle collection anywhere in the world came close. Not only was Sam technically involved, he was an avid historian and his writing style is remarkably entertaining and easily read for a man of such technical ability.

There are many more stories that I've heard about Sam, some even involving his direct experience with the Yamaha twin. Did you ever watch the TV series "Knight Rider" ? Did you know the show also featured a futuristic Knight Rider motorcycle? It was built by Sam around a W2000. And when it comes to the RE5, he's been there, done that; sidecars, belt drives, carb conversions and even supercharging. Not to mention extensive racing experience.

All of this history still exists. Member JESS worked directly with Sam for many years and his accumulated knowledge under the tutelage of Sam himself is priceless. We are very fortunate that Sam's collection wasn't scattered to the ends of the US and beyond and it's essential core remains in very capable hands; the fact that JESS is a member of this board, moreso the benefit for us.

Now the story:

To The Rotary Community:

In answer to the Rotary Twin question, here are my notes on the background

history of the RT Program. Though lengthy, it is important information in

understanding the thinking and direction of Suzuki at that time. This is

very good information for the RE-5 historian, enthusiast, and collector.

Because of the great length of this total story, I will break it down into

sections that I will post over a period of a couple of weeks. The following

information is presented in a "you are there" format:

PART 1:

The Rotary Twin (RT) Development Program was a serious "turning point" for

Suzuki that can't be stressed enough. This decision revolves around one

major factor and event that left such an impact on Suzuki that it shook the

foundation of the Rotary Program and the company. It changed their

strategy, course, and scheduled production of the RE-5.

Suzuki's motorcycle engineering policy has always been "design for today

with tomorrow in mind." Thus, there are built-in provisions to accommodate

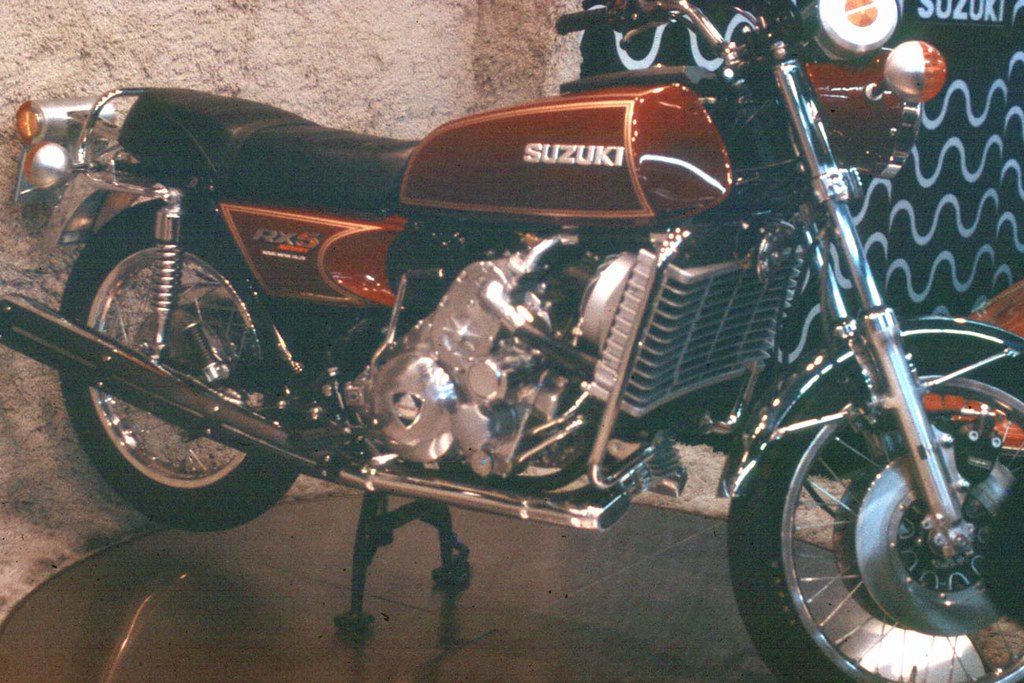

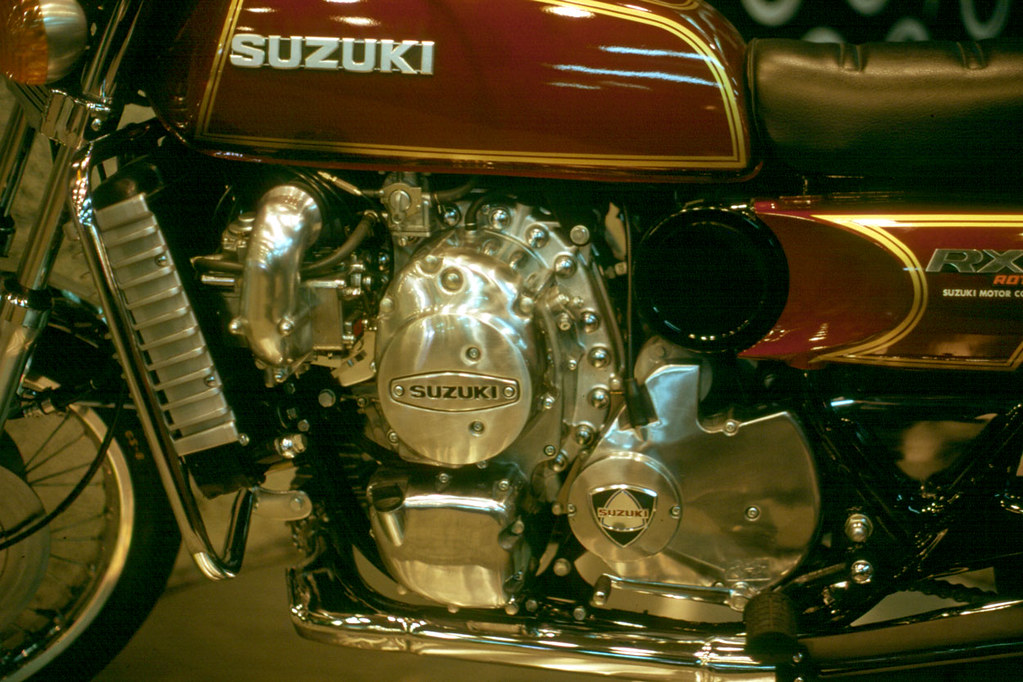

future developments. Looking at an RE-5, certain things just stand out,

such as an oversized radiator, large oil cooler, twin points, hefty

generator, huge twin ducted air box, big 295mm twin front disk, 3-stage CDI

box, and a monster two-barrel carburetor. These were all for today's single

rotor, but designed for tomorrow's twin.

By early August 1972 Suzuki was well along into their quiet Rotary project,

with 12 single rotor prototype machines going through extensive field and

bench testing. At that same time, engineers had a twin-rotor design off the

drawing boards and were working closely with a second R&D team to make up

two twin Rotary prototypes. However, Suzuki knew that the twin rotor would

be the next generation engine in just a few years and already made

provisions for the twin. But, the single rotor had first priority in

development and funding, and the twin was a second-stage fill in. In the

mean time, daily reports on the 12 prototypes showed that the new, improved,

single-Rotary engine developed by R&D performed very well. But, still at

times, it took some slight tweaking and refining. Suzuki Marketing was

pleased with the reports and requested two RX Rotary prototypes and one cut

away engine from R&D wanting to feature them as part of their Suzuki display

at the upcoming Tokyo Motor Show in October, 1972.

The Tokyo Motor Show is the "granddaddy" of them all. Anyone who is anyone

would have been there. This show gives every manufacturer a worldwide

platform to display their latest line up of motorcycles for the forthcoming

1973 season. It also gives them an opportunity to tease and wet the

appetite of both public and press by showing off prototype and concept

machines. Though marketing had a very good idea, their request for two RX

prototypes and a twin cut away engine was rejected because Suzuki did not

want to tip their Rotary hand yet. Somewhat puzzled and disappointed by the

decision from the top, marketing went ahead without the Rotaries. In

October 1972, they set up a fabulous display of 42 machines for '73,

featuring the GT-750K triple taking center stage. The whole R&D team was at

the show and was excited to see what the competition had to offer for '73.

After making three extensive passes around the sprawling show, they returned

back to the Suzuki display and compared notes. The conclusion was Suzuki

had the best display, a terrific line up of machines, the most people, and

more press coverage than anyone else. As far as their Japanese competition

went, Honda had nothing special to speak of but a few warmed up '72 models.

Kawasaki had a new triple to show off, but ho-hum. Yamaha, who was just

across from the big Suzuki display, had a modest line up of bland looking,

so-so machines. The only thing of mention there was a roped-off, covered

display with a sign that read "special sneak preview unveiling at 12:00."

No one on the R&D team gave it much thought.

At around 11:45 a band of reporters were noticed gathering around the Yamaha

display, which now started to slowly revolve. This seemed interesting

enough, so most of the R&D boys made their way over to Yamaha territory

where the crowed was beginning to grow. One reporter said that he heard

that Yamaha had a new, updated version of their prototype GL-750 4 cylinder,

two-stroke, water-cooled, "fuel injection" model ready for production.

Rumors and gossip were abound with all kinds of speculation. At precisely

12:00 the strobe lights went on and fanfare music started to play. This

hype instantly attracted a large crowd, as people started pouring down all

aisles straight for the Yamaha display. With all eyes affixed to the

covered display, two shapely, smiling models came out and slowly walked

around the covered rotating display a few times and pointed to some unseen

bulges. This increased the mystique another notch and drew the crowd in

closer. The strobe lights stopped, and the overhead and side spot lights

took over and fully illuminated the covered display. The two models stepped

back and clapped their hands loudly. At that moment, all the covers on the

display lifted straight up and disappeared into the ceiling rigging...

unveiling... The new Yamaha RZ-201 Twin Rotor Motorcycle! The crowd

clapped, cheered, oooh and ahhhd. The bike was a beauty. Camera flashes

lit up like a Roman candle. Slowly revolving around, the overhead lights

reflected the rich metal flake cinnamon brown-colored tank, accented by twin

white stripes, with a matching contoured tan leather seat. The lower lights

highlighted the radiator and showed off the triple-plated chrome radiator

guards, twin mufflers, side covers, fenders, and wheel rims. The Yamaha

Twin Rotary was absolutely outstanding and stole the show!

Amiss a barrage of questions and a sea of reporters, the Yamaha rep stepped

up to the podium and explained that the RZ-201 was a water-cooled Rotary

with an oil cooler and had a 662cc twin rotary engine that developed 68hp at

6500 rpm, using two Keihin Cu-carbs. They stated that the twin rotors were

uniquely positioned above a five-speed, tuned, syncro meshed transmission

for better weight distribution, handling, and servicing. The twin rotors

were driven by a triple duplex chain and was lubricated by Yamaha's new CCR

system (Charge Cool Rotor - the fuel/air mixture from the carburetor is

mixed with oil for cooling and lubrication of the twin rotors). The bike

comes with dual front disk brakes, which work independently of each other

for safety purposes. In the event of failure, one brake does not negate the

stopping power of the other. The RZ-201 also comes with another Yamaha

first, a hydraulic rear disk brake system. He went on and on and on and

revealed that Yamaha had been working on this twin for years. It was

considered one of the best kept secrets in the industry. He ended his

dissertation by pointing to the RZ-201, stressing it was a fully working and

operational twin rotary, that was tried and tested, was scheduled for full

production, would be available at all Yamaha dealers by mid February, and

that orders were now being taken.

Well... needless to say, the on looking Suzuki R&D team stood there staring,

stunned, and dumbfounded. For one look at this rotary, they all knew there

was no doubt about it. This sleek-looking Yamaha twin "Roadster" was a real

serious threat and was going to give the Suzuki RX5 single rotor a run for

its money, if not bury it! It was at least two years ahead in technology.

To add a little insult to injury, Yamaha reps spotted the Suzuki R&D team

gawking at the RZ-201 green with envy. They sent the two shapely models

over to give them a gift. The first model handed each a press release

packet, which contained color photos, a factory spec sheet, boiler plate

media coverage copy, promo spots, patches, pencils, pricing sheets, etc.

The second model handed each a cardboard tube that contained a large RZ-201

wall poster, calendar, and special first-day unveiling factory brochure.

And... An RZ-201 order form!

Stay tuned for the Part 2....

To The Rotary Community:

ROTARY TWIN STORY -- PART 2:

After getting over the initial shock, the R&D Team went back to the Suzuki

display and talked about the RZ-201. Some of the lingering questions that

kept gnawing at them were:

1. This was the best kept secret in the industry.

2. They could not believe it was made at Yamaha, for quiet inside

sources would have tipped them off.

3. The comment "working on it for years" didn't fit. Where? With who?

4. Why did Yamaha bypass the single rotor and go straight to the twin?

5. Suzuki purchased a full MFG license from NSU/Wankel.

6. Honda and Kawasaki purchased an R&D license only (non-MFG).

7. Where and who did the bike testing (bench and track)?

8. How did Yamaha come up with this machine?

The answer to all of these questions is a story in itself for another time.

** Here is the important turning point: **

The following Monday morning after the show a special, top-level executive

meeting was held at Suzuki. They were now faced with the cold fact and

reality that by mid February the RZ-201 would be on the Yamaha showroom

floors first. This translates into a major cut of the early Rotary market

and that Yamaha, with its foot first in the door, would capture at least

minimum 75 percent market share, thus regulating the Suzuki Rotary as a

"Johnny come lately" (catch up). Not only that, but by drawing people into

the dealers to see the advanced RZ-201 would, in turn, increase Yamaha's

other model sales as well.

Armed with this, Suzuki went into a semi panic. It forced them to kick up

their RX program, fast track all Rotary testing, and give priority and

funding to R&D for the twin Rotary. They also pushed up production of their

new RE-5 by a year and a half. This was done despite loud protests by

engineering, R&D, and marketing. They felt that by rushing the project

would create problems down the road. Their protest was noted but was

overridden.

Between October and early February of 1973, everything was still "fast

track." The two R&D teams were working diligently. The first R&D team

working on the RX project was still ironing out minor kinks in the

single-rotor engine. It attributed some of the problems through outside

parts sourcing. The second R&D RT team put together two twin-Rotary engines

(RT-13 #10013 and RT-14 #10014) and were bench testing them. All eyes were

looking toward mid February when the RZ-201 would hit the Yamaha showrooms.

February passed, and no RZ-201s were to be seen anywhere. Most everyone

figured that they were on their way -- just slow delivery. The first half

of March finds that R&D fitted RT-13 Rotary prototype engine into a test

bed machine using a slightly modified RX frame. Twin testing continued both

on bench with RT-14 and now on the test track with RT-13. Twin information

is somewhat sparse at this time. But notes indicate that, though both

Rotaries ran, problems still persisted with carburetion that had not been

ironed out. RT-13 was running on the test track when the engine blew, due

to seized main shaft bearings from lack of oil and an ongoing problem of

overheating. RT-13's engine was pulled, and R&D took it apart for

inspection. It was never reassembled. The second test model using the

RT-14 engine was put into the RT-13 frame. This was put through extensive

and severe testing. Once again, a few problems kept creeping up. In any

event, Suzuki was confident in the R&D team and felt it was only a matter of

time before the "Twin" was perfected. They sent an encouraging memo to both

R&D teams telling them to keep up the good work and that new improvements in

sealing, metallurgy, coating, carburetion, etc., were coming in shortly from

the expanded NSU/Wankel main information pool. By the end of April, all the

new technology improvements were taken from the pool and were adapted into

the RX single rotor and the RT twin. This cured many of the problems, but

the twin carburetors were still a little tricky at best -- with lingering on

again and off again glitches surfacing. The adaptation of a fiber insulator

block from GM (General Motors) and thicker gasket material from CW (Curtis

Wright) helped out quite a bit.

On May 1, 1973, Yamaha issued a press statement that the RZ-201 would not be

available until mid August due to a minor assembly line teething problem.

Hearing this announcement, both teams were jubilant, for it now bought them

three and a half more months time to work on the engine. And now they were

basically on an even keel with Yamaha, as this brought them to within three

weeks from the next Tokyo Show in September where they could display the

next RX-5 single and the RT-Twin models. They could then go toe to toe

with the RZ-201. While the two R&D teams were jumping for joy, Suzuki

corporate saw the statement as a red flag and did not buy Yahama's story.

They felt there was more to the story than what meets the eye and felt it

was more than an assembly line problem. At this point several rumors

started to circulate:

1. Yamaha's RZ-201 Twin developed major engine problems, and it was

back to the drawing board.

2. Outside source part suppliers for the RZ-201 were running way behind

schedule.

3. Yamaha really had an assembly line problem and was revamping it for

better production flow.

4. Yamaha was trying to raise funds to manufacture the RZ-201 by taking

pre-production orders (?).

The real "zinger" is:

5. Inside sources claimed that the RZ-201 displayed at the show was a

dummy that did not run and that the high-polished engine and transmission

cases were totally empty.

At this point in time, the RZ-201 falls into limbo and disappears. Over the

next three and a half months, we find the R&D team still working on the RX

single, and the RT-14 twin was still giving them some minor sealing

problems, heating problems, carburetor problems, and timing chain and

transmission problems due to the high torque. R&D pointed the finger at

outside source suppliers due to the "fast tracking" and that their quality

control left a lot to be desired.

By late August there was still no sign of RZ-201 activity anywhere. At this

point and because of reliable source information that the bike was a dummy,

Suzuki corporate discounted the RZ-201 as a false alarm and threat and moved

ahead with the major decision to definitely come out with a twin Rotary.

But, for now and in view of the $90 million+ already spent on the Rotary

project, all the tooling is geared for a single. They felt the best

direction to take at that time was to get the RX-500 out into the motorcycle

main stream to try and corner the Rotary market, capture a lion's share, and

then offer a big twin, RT-10, 1000cc Road Cruiser as a new second model

generation for the '77 season.

In September Suzuki set up another fabulous display at the Tokyo Motor Show

and featured three RX-5s: a burgundy, a two-tone firemist blue, and a

two-tone metal flake green. The bikes were the hit of the show, and Suzuki

followed suit and copied Yamaha's giveaway (cardboard tubes with promotional

items in it - wall calendar, factory spec sheet, radio promos, etc.).

** Per the above link, I have placed some photos of some of the items that

were in that cardboard tube. **

Yamaha had a nice display of bikes, but no RZ-201 nor any mention of it

whatsoever. The bike disappeared. The only other Rotaries at the show

were:

1. Sachs had five pre-mix, air-cooled W-2000 models -- two red tanks

(one with a Sachs name badge on the tank and one with a Hercules name badge

on the tank) that featured a single KC27 engine, one yellow tank (with

Hercules name badge) that featured a KM24 single with a shaft drive using a

BMW transmission. They also had two other W-2000s: a black tank with DKW

badge and a blue tank with a Victoria badge. All these were trade names

used They also displayed an inline, working KM914 "Big Twin" Rotary engine

that was going to be offered the following year as an option (see photos

posted). The only other thing of note was that Sachs had two scantily

clad/risqué models walking around showing off the new W-2000 Rotaries.

However, show officials did not like their attire and politely asked them to

change their clothes (see photo).

2. NTV (Nortorn Triumph Villars) had two twin Rotary prototypes on

display. The first used a Sachs KM24 snowmobile engine (all their R&D did

was make two snowmobile engines together). The other used a Sachs KM914

industrial engine and did the same. These machines looked used and tired.

To move along with our story, the next year R&D continued to refine the RX

engine, now called the RE and the RT Twin. In September 1974, the full

production 1975 RE-5M Rotary made its grand debut at the Tokyo Show. Once

again, it was an instant show stopper. On display was an RE-5 in firemist

red, one in firemist blue, plus and RX-5 burgundy model. Though initial

sales and reserve production blocks showed a very promising future for the

new RE-5, sales started to fall off sharply by March 1975 after the public

and press put it through their own street and track testing and long

endurance runs. Problems surfacing with engine seals, first and second

gear, spark plug, and carburetion were the main complaints. This led to

"quiet recalls" to fix the problems. This fast tracking that R&D

engineering and marketing warned about was now starting to catch up.

Most cycle magazines poked fun at the softball turn signals, rolodex gauges,

and coffee can stop light assembly (all of which did not help the sales of

the RE-5). Suzuki was aware that the Italian space age design was ahead of

its time and was reverting back to a more conventional look. However, since

they were loosing serious money on the RE-5M, they opted to give the RE a

cosmetic face lift by using nearly everything on the GT-750 shelf that would

fit. They would now offer the bike as a 1976 "A" model. With new

improvements and corrections to the engine, plus today's styling, they hoped

this would turn everything around and boost Rotary sales. Suzuki still felt

that the Rotary was going to be the power source for all future motorcycles.

Needless to say, due to financial circumstances, the RT-Twin was put on hold

for 1976. But R&D could continue with their twin prototype and experiments.

In April R&D made some engineering advancements and pulled RT-14 #10014 out

of the frame (the engine seized due a Mikuni #37 oil pump going bad) and

added RT-10 #10050 with rear disk brake assembly in its place. They put it

through more testing. It performed smoothly without a hitch and worked

above everyone's expectations. This all was due in part to the addition of

three new members of the R&D team, who came over from Yamaha and worked

directly on the (now canceled) RZ-201 project. They confirmed it and

removed all doubt. The RZ-201 at the show was not a "dummy" but a fully

operational twin "Rotary Rocket" motorcycle that was scheduled for full

production. With them they brought over inside information, notes and

hands-on twin Rotary experience to their Suzuki RT program.

NOTE: RT-10 #10050 was a combination of the best of both engines -- the RT

and RZ Twins.

Please stay tune for the final, short Part 3...

Best regards,

Sam

--------------------------------------------------------------------

To The Rotary Community:

I'm sorry for the delay in getting out this final chapter of the Rotary Twin

Story. I've had my hands full with the City seizing my property via Eminent

Domain. This includes our 10 acres of land, test track facility, museum,

machine shop, Rotary warehouse and storage facilities, and parts

distribution/rebuilding center. Therefore, this is the first opportunity

I've had to provide the end of the story. I would like to now extend my

sincere thanks to attorney Jess Stockwell for sending me important

information in my fight to maintain Rotary Recycle USA! I will keep you all

posted on the outcome...

Now, on with the story...

Part 3:

The new R&D Team listened to suggestions, tips, and recommendations from

riders, mechanics, and dealers regularly, sifting through the many letters

and faxes pertaining to the complex, time-consuming, and often antiquated

task in servicing the Rotary engine. With this in mind, the new R&D Team

built and tested a revolutionary, advanced, state-of-the-art Twin Rotary

(RT-10051) that was modular in design and had enhanced servicing features

that meant that one no longer had to take apart the entire engine to replace

parts or do repairs. A few of the enhanced service modifications made were

an oil sight glass next to the dip stick, and an identical sight glass was

also added to the clutch cover so you could monitor the level of the

transmission oil.

Next, the big clutch cover got a treatment. The "bulge" on the RH side

(185mm - 7-1/2 inches dia.) now had two 6mm allen-head bolts on the face.

By removing the two bolts, the face plate would come off, thus exposing the

complete primary drive gear and clutch assembly, allowing easy replacement

of clutch plates and disks. Also, the timing chain now had a master link.

A removable distributor assembly was added, with a special screw to the

right side that was an alignment provision so you could put a rod through it

to align the timing gear perfectly with the alignment mark on the inside of

the case. The transmission, though it seemed to be part of the complete

unit, was actually separate and could be removed and replaced with a new one

within ten minutes. There was eight different modular assembly features on

this engine, which in essence made it a total breeze to replace almost any

part on it (even by a novice). One of the master features of this engine

was taken from Curtis Wright working with General Motors engineers. On the

top left and right housing assembly, there were two aluminum caps held on by

two 5mm screws. By taking off the caps, which were very similar to the

timing inspection caps, revealed a rotor at 12 o'clock. All one had to do

to change the main seals was push it out one end and insert the new one.

The was reminiscent to the Schick Injector razor blade (push the old one out

and automatically put a new one in its place).

The last Twin R&D made was #10052. This engine was also modular in design.

The only difference was that this was fitted into a shaft drive system. It

was bench tested, performed excellent, and was one step away from being

mounted into a frame that had mag rims. This Twin engine now had four spark

plugs (two for each chamber). This idea was borrowed from Mazda. Then, all

of a sudden and out of no where, R&D received an executive notice from the

front office that the Rotary project was canceled and should come to an

immediate and abrupt halt. Any and all production of the Rotary, including

R&D, should cease immediately. Thus ends the Twin Rotary dream. But the

technical advancements derived from R&D were not in vain, for many of the

ideas and advancements can be found in the GS models.

Epilogue... Though some of the RX and RP prototypes did get away from

Suzuki due to one thing or another, one point is assured -- Suzuki kept all

the blue prints and prototypes of the Twin Rotor models. They still have

them tucked away in their warehouse. Suzuki invested multi millions in

their Rotary dream and envisioned it as the power source of the future.

They were dedicated to that ultimate end. Even after the Rotary project

ceased, Suzuki was still a firm believer in the Rotary and had hopes and

aspirations that it would once again evolve as a power source for future

machines.

With the gas prices of today on a daily rise, a second and third look at the

Rotary engine is being seriously considered by many companies... It has

recently come to our attention that John Deere has been doing some Rotary

experimentation and has come up with a new slant -- let the Rotary stay

constant at 4,000-4,500 rpm. This would give the best gas efficiency. What

they are experimenting with is a hydrostatic transmission that governs the

speed. Therefore, you have an engine running at one constant speed and a

transmission going through all the gears automatically for you. Very unique

and economical. This would answer a multitude of questions and may be the

way to go. It's what Felix Wankel originally had in mind.

Rotary Recycle has also shipped out KM914s, KM24s, and KM27s to NASA in

Cleveland, who are doing extensive research. Also, we've sent test engines

out to Mercury Outboard and Aviation. Honda currently has seven Rotaries in

their R&D department running on hydrogen. Avion Corp. is manufacturing

Rotaries for the military R&D. Plus, there are other Rotary engine

manufacturers making new single and double units that are available on the

open market today. So, the Rotary engine is not dead by any means. It is

quietly alive and well, and it's only a matter of time before technology,

metallurgy, emissions, and gas efficiency push it to the forefront once

again.

Best regards,

Sam Costanzo

Rotary Recycle

EDIT: Buried in some notes I've been collecting for over 20 years was this from Sam:

"...........including 10 painted "ensembles" that were in storage. My notes and records indicate at that time Suzuki R&D rescued 10 prototypes plus ensembles off the loading docks. And my quiet sources at Suzuki state they still have them tucked away in storage. One is the RT-10 twin rotor #10050 in two-tone Firemist Blue. Another is RT-10 twin rotor #10051 in two-tone burgundy with shaft drive and "Road Cruiser" touring package..... However, Suzuki's official factory line is quoted as saying "We don't have any...maybe."

As the years roll on since Sam's passing, I feel I need to give a background as we have so many new members and many new to the RE5 itself.

If you are unfamiliar with the name Sam Costanzo, let me tell you that it was synonymous with "Suzuki RE5" in the US. Sam was directly involved with the Suzuki RE5 project by invitation from Suzuki. He cut his rotary motorcycle teeth with his involvement with the Hercules W2000 and went on to become the leading expert on the Suzuki RE5 outside of the factory itself (he actually lectured on the RE5 at the Japanese factory). In Sam's museum you could take a tour through all sorts of RE5 versions and feast your eyes on literally hundreds of RE5's and W2000's (Sam even had Van Veens- yes, that's plural). No rotary motorcycle collection anywhere in the world came close. Not only was Sam technically involved, he was an avid historian and his writing style is remarkably entertaining and easily read for a man of such technical ability.

There are many more stories that I've heard about Sam, some even involving his direct experience with the Yamaha twin. Did you ever watch the TV series "Knight Rider" ? Did you know the show also featured a futuristic Knight Rider motorcycle? It was built by Sam around a W2000. And when it comes to the RE5, he's been there, done that; sidecars, belt drives, carb conversions and even supercharging. Not to mention extensive racing experience.

All of this history still exists. Member JESS worked directly with Sam for many years and his accumulated knowledge under the tutelage of Sam himself is priceless. We are very fortunate that Sam's collection wasn't scattered to the ends of the US and beyond and it's essential core remains in very capable hands; the fact that JESS is a member of this board, moreso the benefit for us.

Now the story:

To The Rotary Community:

In answer to the Rotary Twin question, here are my notes on the background

history of the RT Program. Though lengthy, it is important information in

understanding the thinking and direction of Suzuki at that time. This is

very good information for the RE-5 historian, enthusiast, and collector.

Because of the great length of this total story, I will break it down into

sections that I will post over a period of a couple of weeks. The following

information is presented in a "you are there" format:

PART 1:

The Rotary Twin (RT) Development Program was a serious "turning point" for

Suzuki that can't be stressed enough. This decision revolves around one

major factor and event that left such an impact on Suzuki that it shook the

foundation of the Rotary Program and the company. It changed their

strategy, course, and scheduled production of the RE-5.

Suzuki's motorcycle engineering policy has always been "design for today

with tomorrow in mind." Thus, there are built-in provisions to accommodate

future developments. Looking at an RE-5, certain things just stand out,

such as an oversized radiator, large oil cooler, twin points, hefty

generator, huge twin ducted air box, big 295mm twin front disk, 3-stage CDI

box, and a monster two-barrel carburetor. These were all for today's single

rotor, but designed for tomorrow's twin.

By early August 1972 Suzuki was well along into their quiet Rotary project,

with 12 single rotor prototype machines going through extensive field and

bench testing. At that same time, engineers had a twin-rotor design off the

drawing boards and were working closely with a second R&D team to make up

two twin Rotary prototypes. However, Suzuki knew that the twin rotor would

be the next generation engine in just a few years and already made

provisions for the twin. But, the single rotor had first priority in

development and funding, and the twin was a second-stage fill in. In the

mean time, daily reports on the 12 prototypes showed that the new, improved,

single-Rotary engine developed by R&D performed very well. But, still at

times, it took some slight tweaking and refining. Suzuki Marketing was

pleased with the reports and requested two RX Rotary prototypes and one cut

away engine from R&D wanting to feature them as part of their Suzuki display

at the upcoming Tokyo Motor Show in October, 1972.

The Tokyo Motor Show is the "granddaddy" of them all. Anyone who is anyone

would have been there. This show gives every manufacturer a worldwide

platform to display their latest line up of motorcycles for the forthcoming

1973 season. It also gives them an opportunity to tease and wet the

appetite of both public and press by showing off prototype and concept

machines. Though marketing had a very good idea, their request for two RX

prototypes and a twin cut away engine was rejected because Suzuki did not

want to tip their Rotary hand yet. Somewhat puzzled and disappointed by the

decision from the top, marketing went ahead without the Rotaries. In

October 1972, they set up a fabulous display of 42 machines for '73,

featuring the GT-750K triple taking center stage. The whole R&D team was at

the show and was excited to see what the competition had to offer for '73.

After making three extensive passes around the sprawling show, they returned

back to the Suzuki display and compared notes. The conclusion was Suzuki

had the best display, a terrific line up of machines, the most people, and

more press coverage than anyone else. As far as their Japanese competition

went, Honda had nothing special to speak of but a few warmed up '72 models.

Kawasaki had a new triple to show off, but ho-hum. Yamaha, who was just

across from the big Suzuki display, had a modest line up of bland looking,

so-so machines. The only thing of mention there was a roped-off, covered

display with a sign that read "special sneak preview unveiling at 12:00."

No one on the R&D team gave it much thought.

At around 11:45 a band of reporters were noticed gathering around the Yamaha

display, which now started to slowly revolve. This seemed interesting

enough, so most of the R&D boys made their way over to Yamaha territory

where the crowed was beginning to grow. One reporter said that he heard

that Yamaha had a new, updated version of their prototype GL-750 4 cylinder,

two-stroke, water-cooled, "fuel injection" model ready for production.

Rumors and gossip were abound with all kinds of speculation. At precisely

12:00 the strobe lights went on and fanfare music started to play. This

hype instantly attracted a large crowd, as people started pouring down all

aisles straight for the Yamaha display. With all eyes affixed to the

covered display, two shapely, smiling models came out and slowly walked

around the covered rotating display a few times and pointed to some unseen

bulges. This increased the mystique another notch and drew the crowd in

closer. The strobe lights stopped, and the overhead and side spot lights

took over and fully illuminated the covered display. The two models stepped

back and clapped their hands loudly. At that moment, all the covers on the

display lifted straight up and disappeared into the ceiling rigging...

unveiling... The new Yamaha RZ-201 Twin Rotor Motorcycle! The crowd

clapped, cheered, oooh and ahhhd. The bike was a beauty. Camera flashes

lit up like a Roman candle. Slowly revolving around, the overhead lights

reflected the rich metal flake cinnamon brown-colored tank, accented by twin

white stripes, with a matching contoured tan leather seat. The lower lights

highlighted the radiator and showed off the triple-plated chrome radiator

guards, twin mufflers, side covers, fenders, and wheel rims. The Yamaha

Twin Rotary was absolutely outstanding and stole the show!

Amiss a barrage of questions and a sea of reporters, the Yamaha rep stepped

up to the podium and explained that the RZ-201 was a water-cooled Rotary

with an oil cooler and had a 662cc twin rotary engine that developed 68hp at

6500 rpm, using two Keihin Cu-carbs. They stated that the twin rotors were

uniquely positioned above a five-speed, tuned, syncro meshed transmission

for better weight distribution, handling, and servicing. The twin rotors

were driven by a triple duplex chain and was lubricated by Yamaha's new CCR

system (Charge Cool Rotor - the fuel/air mixture from the carburetor is

mixed with oil for cooling and lubrication of the twin rotors). The bike

comes with dual front disk brakes, which work independently of each other

for safety purposes. In the event of failure, one brake does not negate the

stopping power of the other. The RZ-201 also comes with another Yamaha

first, a hydraulic rear disk brake system. He went on and on and on and

revealed that Yamaha had been working on this twin for years. It was

considered one of the best kept secrets in the industry. He ended his

dissertation by pointing to the RZ-201, stressing it was a fully working and

operational twin rotary, that was tried and tested, was scheduled for full

production, would be available at all Yamaha dealers by mid February, and

that orders were now being taken.

Well... needless to say, the on looking Suzuki R&D team stood there staring,

stunned, and dumbfounded. For one look at this rotary, they all knew there

was no doubt about it. This sleek-looking Yamaha twin "Roadster" was a real

serious threat and was going to give the Suzuki RX5 single rotor a run for

its money, if not bury it! It was at least two years ahead in technology.

To add a little insult to injury, Yamaha reps spotted the Suzuki R&D team

gawking at the RZ-201 green with envy. They sent the two shapely models

over to give them a gift. The first model handed each a press release

packet, which contained color photos, a factory spec sheet, boiler plate

media coverage copy, promo spots, patches, pencils, pricing sheets, etc.

The second model handed each a cardboard tube that contained a large RZ-201

wall poster, calendar, and special first-day unveiling factory brochure.

And... An RZ-201 order form!

Stay tuned for the Part 2....

To The Rotary Community:

ROTARY TWIN STORY -- PART 2:

After getting over the initial shock, the R&D Team went back to the Suzuki

display and talked about the RZ-201. Some of the lingering questions that

kept gnawing at them were:

1. This was the best kept secret in the industry.

2. They could not believe it was made at Yamaha, for quiet inside

sources would have tipped them off.

3. The comment "working on it for years" didn't fit. Where? With who?

4. Why did Yamaha bypass the single rotor and go straight to the twin?

5. Suzuki purchased a full MFG license from NSU/Wankel.

6. Honda and Kawasaki purchased an R&D license only (non-MFG).

7. Where and who did the bike testing (bench and track)?

8. How did Yamaha come up with this machine?

The answer to all of these questions is a story in itself for another time.

** Here is the important turning point: **

The following Monday morning after the show a special, top-level executive

meeting was held at Suzuki. They were now faced with the cold fact and

reality that by mid February the RZ-201 would be on the Yamaha showroom

floors first. This translates into a major cut of the early Rotary market

and that Yamaha, with its foot first in the door, would capture at least

minimum 75 percent market share, thus regulating the Suzuki Rotary as a

"Johnny come lately" (catch up). Not only that, but by drawing people into

the dealers to see the advanced RZ-201 would, in turn, increase Yamaha's

other model sales as well.

Armed with this, Suzuki went into a semi panic. It forced them to kick up

their RX program, fast track all Rotary testing, and give priority and

funding to R&D for the twin Rotary. They also pushed up production of their

new RE-5 by a year and a half. This was done despite loud protests by

engineering, R&D, and marketing. They felt that by rushing the project

would create problems down the road. Their protest was noted but was

overridden.

Between October and early February of 1973, everything was still "fast

track." The two R&D teams were working diligently. The first R&D team

working on the RX project was still ironing out minor kinks in the

single-rotor engine. It attributed some of the problems through outside

parts sourcing. The second R&D RT team put together two twin-Rotary engines

(RT-13 #10013 and RT-14 #10014) and were bench testing them. All eyes were

looking toward mid February when the RZ-201 would hit the Yamaha showrooms.

February passed, and no RZ-201s were to be seen anywhere. Most everyone

figured that they were on their way -- just slow delivery. The first half

of March finds that R&D fitted RT-13 Rotary prototype engine into a test

bed machine using a slightly modified RX frame. Twin testing continued both

on bench with RT-14 and now on the test track with RT-13. Twin information

is somewhat sparse at this time. But notes indicate that, though both

Rotaries ran, problems still persisted with carburetion that had not been

ironed out. RT-13 was running on the test track when the engine blew, due

to seized main shaft bearings from lack of oil and an ongoing problem of

overheating. RT-13's engine was pulled, and R&D took it apart for

inspection. It was never reassembled. The second test model using the

RT-14 engine was put into the RT-13 frame. This was put through extensive

and severe testing. Once again, a few problems kept creeping up. In any

event, Suzuki was confident in the R&D team and felt it was only a matter of

time before the "Twin" was perfected. They sent an encouraging memo to both

R&D teams telling them to keep up the good work and that new improvements in

sealing, metallurgy, coating, carburetion, etc., were coming in shortly from

the expanded NSU/Wankel main information pool. By the end of April, all the

new technology improvements were taken from the pool and were adapted into

the RX single rotor and the RT twin. This cured many of the problems, but

the twin carburetors were still a little tricky at best -- with lingering on

again and off again glitches surfacing. The adaptation of a fiber insulator

block from GM (General Motors) and thicker gasket material from CW (Curtis

Wright) helped out quite a bit.

On May 1, 1973, Yamaha issued a press statement that the RZ-201 would not be

available until mid August due to a minor assembly line teething problem.

Hearing this announcement, both teams were jubilant, for it now bought them

three and a half more months time to work on the engine. And now they were

basically on an even keel with Yamaha, as this brought them to within three

weeks from the next Tokyo Show in September where they could display the

next RX-5 single and the RT-Twin models. They could then go toe to toe

with the RZ-201. While the two R&D teams were jumping for joy, Suzuki

corporate saw the statement as a red flag and did not buy Yahama's story.

They felt there was more to the story than what meets the eye and felt it

was more than an assembly line problem. At this point several rumors

started to circulate:

1. Yamaha's RZ-201 Twin developed major engine problems, and it was

back to the drawing board.

2. Outside source part suppliers for the RZ-201 were running way behind

schedule.

3. Yamaha really had an assembly line problem and was revamping it for

better production flow.

4. Yamaha was trying to raise funds to manufacture the RZ-201 by taking

pre-production orders (?).

The real "zinger" is:

5. Inside sources claimed that the RZ-201 displayed at the show was a

dummy that did not run and that the high-polished engine and transmission

cases were totally empty.

At this point in time, the RZ-201 falls into limbo and disappears. Over the

next three and a half months, we find the R&D team still working on the RX

single, and the RT-14 twin was still giving them some minor sealing

problems, heating problems, carburetor problems, and timing chain and

transmission problems due to the high torque. R&D pointed the finger at

outside source suppliers due to the "fast tracking" and that their quality

control left a lot to be desired.

By late August there was still no sign of RZ-201 activity anywhere. At this

point and because of reliable source information that the bike was a dummy,

Suzuki corporate discounted the RZ-201 as a false alarm and threat and moved

ahead with the major decision to definitely come out with a twin Rotary.

But, for now and in view of the $90 million+ already spent on the Rotary

project, all the tooling is geared for a single. They felt the best

direction to take at that time was to get the RX-500 out into the motorcycle

main stream to try and corner the Rotary market, capture a lion's share, and

then offer a big twin, RT-10, 1000cc Road Cruiser as a new second model

generation for the '77 season.

In September Suzuki set up another fabulous display at the Tokyo Motor Show

and featured three RX-5s: a burgundy, a two-tone firemist blue, and a

two-tone metal flake green. The bikes were the hit of the show, and Suzuki

followed suit and copied Yamaha's giveaway (cardboard tubes with promotional

items in it - wall calendar, factory spec sheet, radio promos, etc.).

** Per the above link, I have placed some photos of some of the items that

were in that cardboard tube. **

Yamaha had a nice display of bikes, but no RZ-201 nor any mention of it

whatsoever. The bike disappeared. The only other Rotaries at the show

were:

1. Sachs had five pre-mix, air-cooled W-2000 models -- two red tanks

(one with a Sachs name badge on the tank and one with a Hercules name badge

on the tank) that featured a single KC27 engine, one yellow tank (with

Hercules name badge) that featured a KM24 single with a shaft drive using a

BMW transmission. They also had two other W-2000s: a black tank with DKW

badge and a blue tank with a Victoria badge. All these were trade names

used They also displayed an inline, working KM914 "Big Twin" Rotary engine

that was going to be offered the following year as an option (see photos

posted). The only other thing of note was that Sachs had two scantily

clad/risqué models walking around showing off the new W-2000 Rotaries.

However, show officials did not like their attire and politely asked them to

change their clothes (see photo).

2. NTV (Nortorn Triumph Villars) had two twin Rotary prototypes on

display. The first used a Sachs KM24 snowmobile engine (all their R&D did

was make two snowmobile engines together). The other used a Sachs KM914

industrial engine and did the same. These machines looked used and tired.

To move along with our story, the next year R&D continued to refine the RX

engine, now called the RE and the RT Twin. In September 1974, the full

production 1975 RE-5M Rotary made its grand debut at the Tokyo Show. Once

again, it was an instant show stopper. On display was an RE-5 in firemist

red, one in firemist blue, plus and RX-5 burgundy model. Though initial

sales and reserve production blocks showed a very promising future for the

new RE-5, sales started to fall off sharply by March 1975 after the public

and press put it through their own street and track testing and long

endurance runs. Problems surfacing with engine seals, first and second

gear, spark plug, and carburetion were the main complaints. This led to

"quiet recalls" to fix the problems. This fast tracking that R&D

engineering and marketing warned about was now starting to catch up.

Most cycle magazines poked fun at the softball turn signals, rolodex gauges,

and coffee can stop light assembly (all of which did not help the sales of

the RE-5). Suzuki was aware that the Italian space age design was ahead of

its time and was reverting back to a more conventional look. However, since

they were loosing serious money on the RE-5M, they opted to give the RE a

cosmetic face lift by using nearly everything on the GT-750 shelf that would

fit. They would now offer the bike as a 1976 "A" model. With new

improvements and corrections to the engine, plus today's styling, they hoped

this would turn everything around and boost Rotary sales. Suzuki still felt

that the Rotary was going to be the power source for all future motorcycles.

Needless to say, due to financial circumstances, the RT-Twin was put on hold

for 1976. But R&D could continue with their twin prototype and experiments.

In April R&D made some engineering advancements and pulled RT-14 #10014 out

of the frame (the engine seized due a Mikuni #37 oil pump going bad) and

added RT-10 #10050 with rear disk brake assembly in its place. They put it

through more testing. It performed smoothly without a hitch and worked

above everyone's expectations. This all was due in part to the addition of

three new members of the R&D team, who came over from Yamaha and worked

directly on the (now canceled) RZ-201 project. They confirmed it and

removed all doubt. The RZ-201 at the show was not a "dummy" but a fully

operational twin "Rotary Rocket" motorcycle that was scheduled for full

production. With them they brought over inside information, notes and

hands-on twin Rotary experience to their Suzuki RT program.

NOTE: RT-10 #10050 was a combination of the best of both engines -- the RT

and RZ Twins.

Please stay tune for the final, short Part 3...

Best regards,

Sam

--------------------------------------------------------------------

To The Rotary Community:

I'm sorry for the delay in getting out this final chapter of the Rotary Twin

Story. I've had my hands full with the City seizing my property via Eminent

Domain. This includes our 10 acres of land, test track facility, museum,

machine shop, Rotary warehouse and storage facilities, and parts

distribution/rebuilding center. Therefore, this is the first opportunity

I've had to provide the end of the story. I would like to now extend my

sincere thanks to attorney Jess Stockwell for sending me important

information in my fight to maintain Rotary Recycle USA! I will keep you all

posted on the outcome...

Now, on with the story...

Part 3:

The new R&D Team listened to suggestions, tips, and recommendations from

riders, mechanics, and dealers regularly, sifting through the many letters

and faxes pertaining to the complex, time-consuming, and often antiquated

task in servicing the Rotary engine. With this in mind, the new R&D Team

built and tested a revolutionary, advanced, state-of-the-art Twin Rotary

(RT-10051) that was modular in design and had enhanced servicing features

that meant that one no longer had to take apart the entire engine to replace

parts or do repairs. A few of the enhanced service modifications made were

an oil sight glass next to the dip stick, and an identical sight glass was

also added to the clutch cover so you could monitor the level of the

transmission oil.

Next, the big clutch cover got a treatment. The "bulge" on the RH side

(185mm - 7-1/2 inches dia.) now had two 6mm allen-head bolts on the face.

By removing the two bolts, the face plate would come off, thus exposing the

complete primary drive gear and clutch assembly, allowing easy replacement

of clutch plates and disks. Also, the timing chain now had a master link.

A removable distributor assembly was added, with a special screw to the

right side that was an alignment provision so you could put a rod through it

to align the timing gear perfectly with the alignment mark on the inside of

the case. The transmission, though it seemed to be part of the complete

unit, was actually separate and could be removed and replaced with a new one

within ten minutes. There was eight different modular assembly features on

this engine, which in essence made it a total breeze to replace almost any

part on it (even by a novice). One of the master features of this engine

was taken from Curtis Wright working with General Motors engineers. On the

top left and right housing assembly, there were two aluminum caps held on by

two 5mm screws. By taking off the caps, which were very similar to the

timing inspection caps, revealed a rotor at 12 o'clock. All one had to do

to change the main seals was push it out one end and insert the new one.

The was reminiscent to the Schick Injector razor blade (push the old one out

and automatically put a new one in its place).

The last Twin R&D made was #10052. This engine was also modular in design.

The only difference was that this was fitted into a shaft drive system. It

was bench tested, performed excellent, and was one step away from being

mounted into a frame that had mag rims. This Twin engine now had four spark

plugs (two for each chamber). This idea was borrowed from Mazda. Then, all

of a sudden and out of no where, R&D received an executive notice from the

front office that the Rotary project was canceled and should come to an

immediate and abrupt halt. Any and all production of the Rotary, including

R&D, should cease immediately. Thus ends the Twin Rotary dream. But the

technical advancements derived from R&D were not in vain, for many of the

ideas and advancements can be found in the GS models.

Epilogue... Though some of the RX and RP prototypes did get away from

Suzuki due to one thing or another, one point is assured -- Suzuki kept all

the blue prints and prototypes of the Twin Rotor models. They still have

them tucked away in their warehouse. Suzuki invested multi millions in

their Rotary dream and envisioned it as the power source of the future.

They were dedicated to that ultimate end. Even after the Rotary project

ceased, Suzuki was still a firm believer in the Rotary and had hopes and

aspirations that it would once again evolve as a power source for future

machines.

With the gas prices of today on a daily rise, a second and third look at the

Rotary engine is being seriously considered by many companies... It has

recently come to our attention that John Deere has been doing some Rotary

experimentation and has come up with a new slant -- let the Rotary stay

constant at 4,000-4,500 rpm. This would give the best gas efficiency. What

they are experimenting with is a hydrostatic transmission that governs the

speed. Therefore, you have an engine running at one constant speed and a

transmission going through all the gears automatically for you. Very unique

and economical. This would answer a multitude of questions and may be the

way to go. It's what Felix Wankel originally had in mind.

Rotary Recycle has also shipped out KM914s, KM24s, and KM27s to NASA in

Cleveland, who are doing extensive research. Also, we've sent test engines

out to Mercury Outboard and Aviation. Honda currently has seven Rotaries in

their R&D department running on hydrogen. Avion Corp. is manufacturing

Rotaries for the military R&D. Plus, there are other Rotary engine

manufacturers making new single and double units that are available on the

open market today. So, the Rotary engine is not dead by any means. It is

quietly alive and well, and it's only a matter of time before technology,

metallurgy, emissions, and gas efficiency push it to the forefront once

again.

Best regards,

Sam Costanzo

Rotary Recycle

EDIT: Buried in some notes I've been collecting for over 20 years was this from Sam:

"...........including 10 painted "ensembles" that were in storage. My notes and records indicate at that time Suzuki R&D rescued 10 prototypes plus ensembles off the loading docks. And my quiet sources at Suzuki state they still have them tucked away in storage. One is the RT-10 twin rotor #10050 in two-tone Firemist Blue. Another is RT-10 twin rotor #10051 in two-tone burgundy with shaft drive and "Road Cruiser" touring package..... However, Suzuki's official factory line is quoted as saying "We don't have any...maybe."

...... well, you know that's what I do Andy! Thanks for the Mazda info. They were well ahead of the bike projects by those dates.

...... well, you know that's what I do Andy! Thanks for the Mazda info. They were well ahead of the bike projects by those dates.